Precautions for thermal decomposition of oily sludge

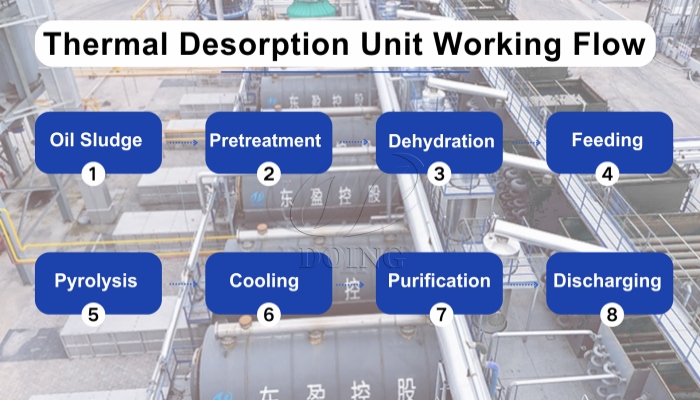

Thermal decomposition of oily sludge involves decomposing the oily sludge at high temperatures, breaking down the pollutants into fuel oil and waste residue. As a professional supplier of thermal decomposition equipment, DOING emphasizes the importance of precautions during the thermal decomposition process of oily sludge to ensure safety, efficiency, and environmental compliance. Below is a detailed and enhanced guide on the precautions for thermal decomposition of oily sludge:

1. Feedstock Pre-treatment

Proper pre-treatment of oily sludge is essential for efficient thermal decomposition. This includes:

Dewatering(Optional): Reducing the moisture content of the oily sludge to improve thermal decomposition efficiency and reduce energy consumption.

Size Reduction(Optional): Grinding or crushing the oily sludge into smaller particles increases the surface area exposed to heat, promoting more complete and faster thermal decomposition reactions.

DOING oily sludge thermal decomposition equipment

2. Temperature Control

The thermal decomposition equipment provided by DOING typically operates within a temperature range of 300-600℃. Precise temperature control is crucial for effective thermal decomposition of organic matter and to prevent equipment damage.

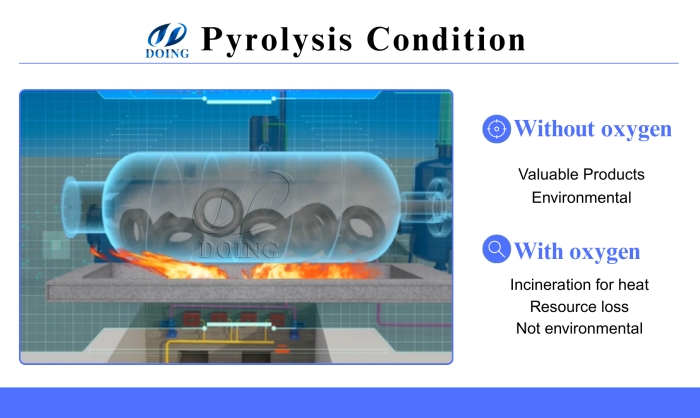

3. Anaerobic-oxygen Environment

A strictly oxygen-free environment is imperative during the thermal decomposition process. Oxygen presence can lead to unintended combustion reactions, reducing treatment efficiency and posing safety hazards. To maintain this environment, the thermal decomposition reactor need to be equipped with advanced sealing systems to prevent air ingress. DOING's thermal decomposition equipment excels in this regard.

Oily sludge anaerobic-oxygen thermal decomposition equipment

4. Selection of Thermal Decomposition Reactor Materials

Oily sludge often contains higher levels of sulfur compared to conventional materials such as tires and plastics. Sulfur can cause severe corrosion to reactor vessels over time. While Q345R steel is commonly used in general thermal decomposition applications, there is a concern that it may cause corrosion to the reaction vessel after long-term oil sludge pyrolysis operation. DOING recommends stainless steel plates for constructing reactor vessels when processing such feedstocks. Stainless steel offers superior resistance to sulfur-induced corrosion, ensuring longer equipment lifespan and reducing maintenance costs. Although stainless steel may have a higher initial investment cost, its long-term benefits in terms of durability and operational reliability make it a cost-effective choice for high-sulfur oily sludge thermal decomposition.

Advantages of stainless steel thermal decomposition equipment

5. Equipment Operation Specifications

Before starting the thermal decomposition equipment, thorough preheating is necessary to ensure uniform temperature distribution throughout the reactor. This step is crucial for achieving consistent thermal decomposition results and preventing thermal stress on the equipment.

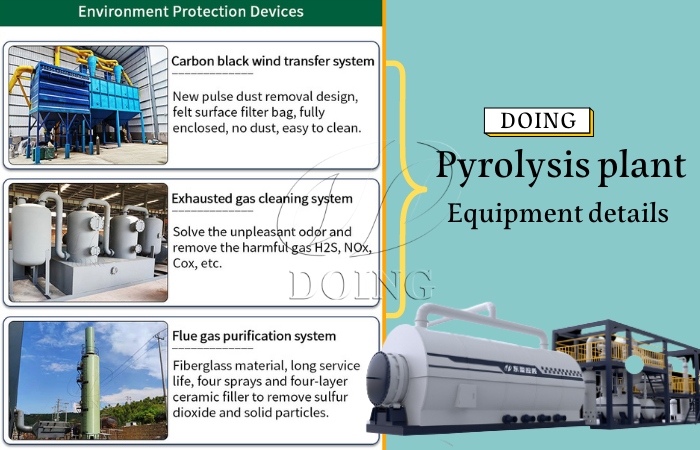

During the thermal decomposition process, the generated oil and gas are condensed and collected in oil tanks. The waste residue is efficiently transported and stored using DOING's specialized screw conveyor system. Exhaust gas and flue gas produced during the thermal decomposition process undergo rigorous treatment. DOING's patented exhaust gas odor removal technology and flue gas desulfurization and denitrification systems ensure that emissions meet environmental standards, minimizing the impact on the surrounding environment.

Oily sludge thermal decomposition equipment working flow

6. Safety Precautions

Regular inspection and maintenance of safety devices such as pressure relief valves and temperature sensors are mandatory to ensure they function correctly under all operating conditions.

Operators should be trained in emergency response procedures, including shutdown protocols and handling of unexpected situations like gas leaks or overheating.

The thermal decomposition equipment should be equipped with comprehensive fire suppression systems and adequate ventilation to mitigate fire risks and ensure a safe working environment.

DOING thermal decomposition equipment safety devices

7. Environmental Monitoring and Compliance

Continuous monitoring of emissions is essential to ensure compliance with environmental regulations. Regular testing of exhaust gases for pollutants such as sulfur dioxide, nitrogen oxides, and particulate matter should be conducted. DOING's advanced emission control systems are designed to achieve significant reductions in these pollutants, helping facilities meet stringent environmental standards and reducing the environmental footprint of the thermal decomposition process.

DOING thermal decomposition equipment environment protection devices

By adhering to these detailed precautions, thermal decomposition equipments can achieve efficient, safe, and environmentally friendly treatment of oily sludge, converting waste into valuable resources while protecting equipment and the environment.

DOING thermal decomposition equipment environment manufacturer services

If you have any further questions or require customized solutions for your oily sludge thermal decomposition project, please do not hesitate to contact DOING Company. Our team of experts is ready to assist you and provide comprehensive support throughout your journey towards waste thermal decomposition business.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia

-

15 TPD used tyre pyrolysis machine produced fuel oil in Brazil