What is the Pyrolysis Temperature of Rubber?

Pyrolysis is a thermal degradation process that breaks down complex polymer chains in the absence of oxygen. When applied to rubber, pyrolysis converts waste materials like tires or industrial rubber into valuable products such as fuel oil, carbon black, and steel wire. The process involves heating rubber to specific temperatures, which vary slightly based on the type of rubber and its physical properties.

DOING waste rubber pyrolysis plant

Key Temperature Ranges for Rubber Pyrolysis

Preheating Phase (160°C):

During the initial phase of pyrolysis, the rubber is heated to approximately 160°C. This stage serves two primary purposes:

1.Removing residual moisture from the rubber, which could otherwise cause instability during the decomposition process.

2. Softening the rubber, making it more amenable to thermal breakdown.

For rubber with high moisture content (e.g., freshly processed scrap), this preheating phase may require additional time to ensure complete drying.

Oil Extraction Phase (200-300°C):

After preheating, the temperature is raised steadily to between 200°C and 300°C. This is the critical range where rubber undergoes pyrolysis, breaking down into lighter hydrocarbons that form fuel oil. The heating rate during this phase is typically controlled at 1-2°C per minute to ensure efficient and uniform decomposition. The phase generally lasts 8-10 hours. Then increase the firepower to make the temperature exceed 300 degrees, and all the remaining raw materials that are not well pyrolysised are heated and pyrolysisted until the temperature starts to drop, and when the temperature drops to 250°C, turn off all the burners.Whole heating process is about 10-12 hours. Monitoring the oil discharge rate is crucial, as a sudden drop in oil output may indicate that the temperature needs adjustment.

Pyrolysis oil yiled of rubber materials

Cooling Phase:

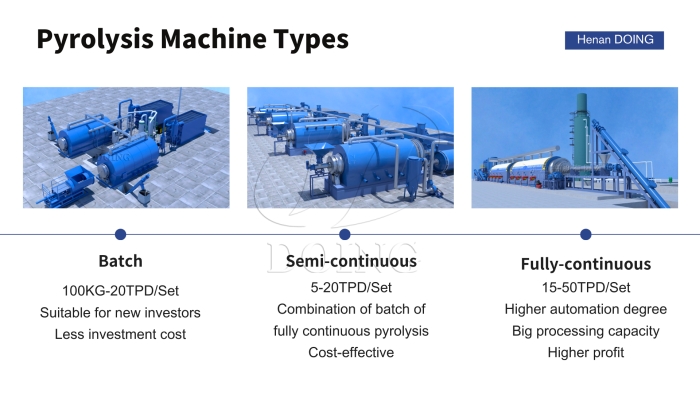

If you operate a batch rubber pyrolsis plant, once the oil extraction is complete, the pyrolysis reactor is cooled gradually to below 80°C or 60°C. At this stage, carbon black can be safely collected and stored. Effective cooling systems, such as forced air circulation using a draft fan (e.g., 15kW capacity), can significantly reduce cooling time to as 4-5 hours. If you adopt the semi-continuous or fully continuous rubber pyrolysis plant, then the recovered carbon black can be discharged at high temperatures.

DOING pyrolysis plant working process

Factors Affecting Rubber Pyrolysis Temperature

Rubber Type:

Natural Rubber: Natural rubber has a less complex molecular structure compared to synthetic rubber, requiring slightly lower temperatures (closer to 200°C) for effective oil extraction.

Synthetic Rubber and Tire Rubber: Synthetic rubbers, particularly those found in vehicle tires, contain higher amounts of sulfur and reinforcing agents like carbon black. These additives increase the thermal stability of the rubber, necessitating temperatures closer to 300°C for complete decomposition.

Waste rubber pyrolysis raw materials

Moisture Content:

Moisture in rubber can interfere with pyrolysis efficiency. Pre-drying steps or extended preheating times may be required for wet rubber.

Additives and Compounding Agents:

Rubber products often contain additives like antioxidants, plasticizers, and sulfur. These agents can influence the final yield of pyrolysis products.

Reactor Design and Heating Method:

The efficiency of heat transfer within the pyrolysis reactor directly impacts the required temperature and process duration. Advanced reactors with uniform heating and efficient temperature control can operate at slightly lower temperatures while maintaining productivity.

DOING waste rubber pyrolysis plant manufacturer

In conclusion, the pyrolysis temperature of rubber is not a fixed value but rather a range that depends on the type of rubber and the specific conditions of the pyrolysis process. And different rubber pyrolysis temperatures will influence the final products yields:

Lower Rubber Pyrolysis Temperatures (e.g.,200-300 °C): Primarily produces liquid volatile hydrocarbons, maily rubber pyrolysis oil.

Higher Rubber Pyrolysis Temperatures (e.g., 400-600 °C): Leads to increased production of gases and char, as the liquid fraction decreases. Understanding these factors is essential for optimizing the pyrolysis process and maximizing the recovery of valuable products from rubber waste.

At DOING Company, we're dedicated to turning rubber waste into valuable resources through our efficient pyrolysis plants. If you're looking to convert rubber waste into fuel oil and other resources, consider partnering with us. Our experienced team ensures that your pyrolysis buisness is cost-effective and efficient.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated