Waste tire recycling rubber powder machine

1.To granulate radial tires into fine rubber crumb of 5~200 mesh with steel and fiber completely recycled at ambient temperature.

2.The input is whole tires,after the processing,steel is completely separated and fiber can be separated up to 95% or above.The finish product is high and competitive in the market

3.Tight construction, small space and simple technique flow.

4. Low energy-consuming and good performance-cost ratio

5.Hight automatization, fewer labors requirement.

6.Reasonable construction,easy operation and low rate of breakdown

7.Environmental-protection,no pollution(no waste gas,no waste residue,no polluted water),meeting the environmental requirement of the government.

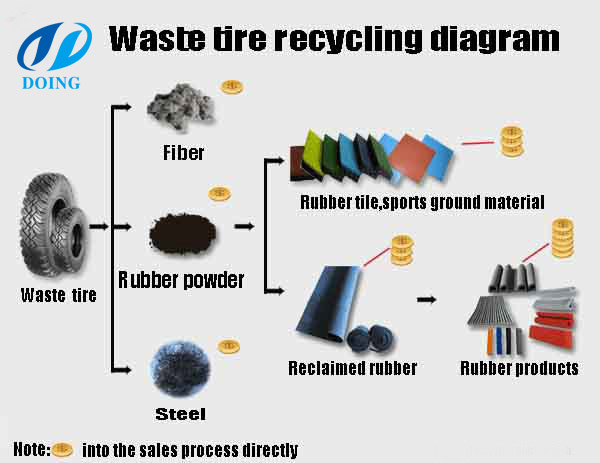

flow chart of waste tire recycling rubber powder machine

Function:Our whole waste tires recycling rubber powder machine is used to make waste tires and rubber powder.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?