How do you dispose of used lubricants?

During the maintenance and use of automobiles, a large amount of waste lubricating oil will be generated. These waste lubricating oil contains a variety of harmful substances, such as heavy metals, polycyclic aromatic hydrocarbons, sulfides, etc. If these waste lubricating oils are not handled properly, they will not only cause serious pollution to the environment, but may also violate relevant laws and regulations. Therefore, it is particularly important to understand and master the proper treatment methods and environmentally friendly treatment methods of waste lubricating oils.

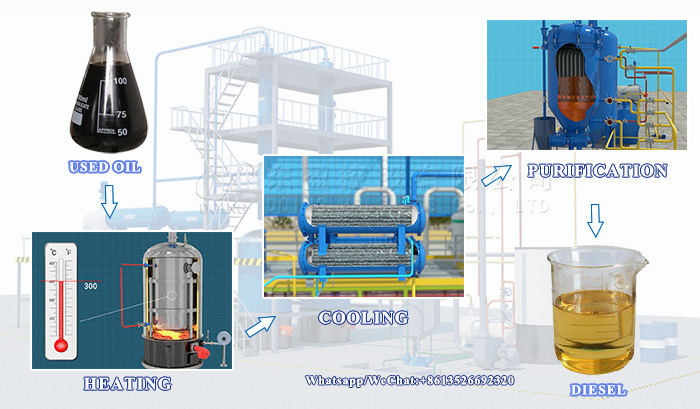

Process of DOING used lubricants dispose machine

Process of DOING used lubricants dispose machine

If the amount of waste lubricating oil you want to dispose is small, you can sell it directly to the waste oil recycling center. You can search for recycling centers near you on Google. For large quantities of waste lubricating oil to be treated, common methods for treating used lubricants include incineration, landfill, and recycling—but each has distinct advantages and drawbacks. Incineration in facilities with strict pollution controls can convert organic matter into heat energy, yet high-temperature combustion may release dioxins and other toxic gases if not meticulously managed. This method is energy-intensive and offers no material recovery, making it less sustainable compared to recycling. Landfilling is strongly discouraged due to the risk of oil seepage into soil and groundwater, causing long-term ecological damage; even when pre-treated to meet standards, it eliminates the possibility of resource reuse and poses ongoing environmental liabilities.

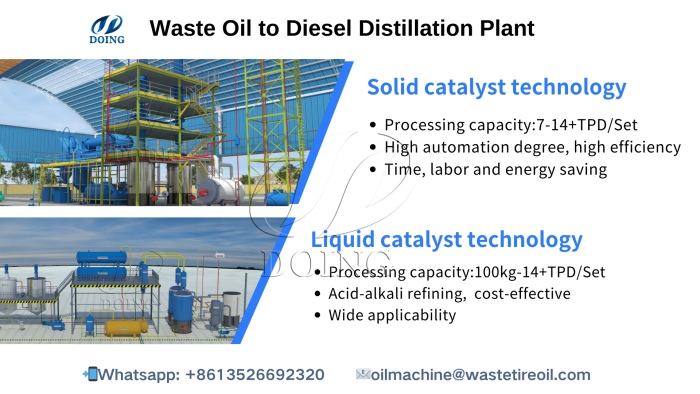

Used lubricants to diesel distillation machine

Used lubricants to diesel distillation machine

The most efficient and sustainable approach is recycling waste oil through advanced distillation technology, which reduces environmental harm while creating economic value by transforming waste into reusable fuel. DOING specializes in waste oil recycling field for more than 14 yearsold, offering two cutting-edge solutions: acid-base washing type and catalyst-based distillation machine designed to maximize resource recovery and can guarantee an oil yield of up to 85%. The processed diesel meets industrial fuel standards and is ideal for boiler plants, steel mills, heavy trucks and agricultural machinery. (Recommended reading: Waste oil to diesel)

DOING used lubricants dispose machine

DOING used lubricants dispose machine

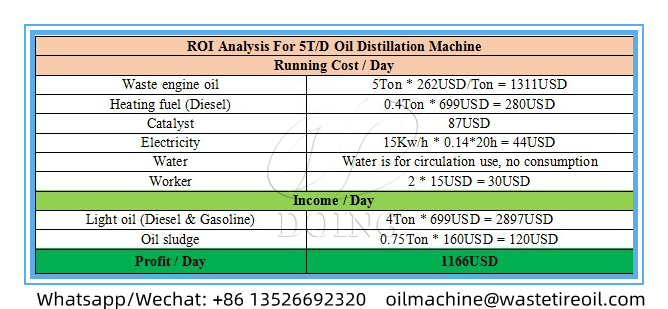

By adopting advanced recycling solutions like DOING used lubricants distillation machines, businesses can reduce disposal costs, comply with environmental regulations, and create a sustainable revenue stream from recycled diesel. This is a profit analysis table prepared by DOING based on customer feedback and market research for your reference:

Dispose used lubricants to diesel ROI analysis

Dispose used lubricants to diesel ROI analysis

Now, more and more customers from different regions, countries, and industries are learning about this equipment. DOING Group combines technical innovation with global expertise, providing end-to-end support from equipment selection to after-sales service. If you are interested in recycling used lubricants, welcome to contact us.

PREV:What is the Difference Between VDU (Vacuum Distillation Unit) and CDU (Crude Distillation Unit)?

PREV:What is the Difference Between VDU (Vacuum Distillation Unit) and CDU (Crude Distillation Unit)?

NEXT:Design and construction of waste motor oil (WMO)to diesel machine

NEXT:Design and construction of waste motor oil (WMO)to diesel machine

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated