Design and construction of waste motor oil (WMO)to diesel machine

DOING waste oil distillation machine can further refine waste motor oil into diesel for fuel. After proper treatment, the diesel obtained from waste motor oil can be used for Euro 2 to Euro 4 standard engines.

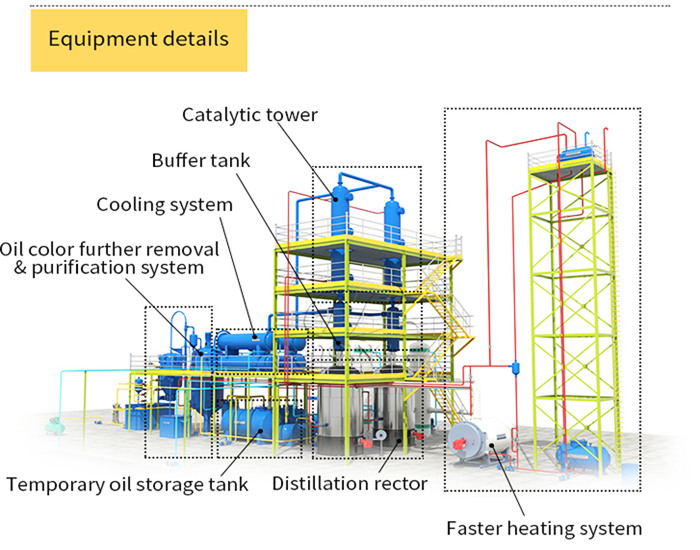

DOING complete waste motor oil to diesel machine consist of heat transfer oil stove, distillation reactor; condenser, decolorizing system, desulfurization tower, with different model and processing capacity: from 0.1 TPD skid-mounted type to 14TPD continuous type.

Waste motor oil distillation machine design

Waste motor oil distillation machine design

DOING designed two types of waste motor oil (WMO) to diesel machine, one is the normal design waste motor oil (WMO) to diesel machine with acid-alkali washing technology, and the other one is the new design waste motor oil (WMO) to diesel machine with solid catalyst technology, among which our new design 10TPD waste oil to diesel machine is very popular with customers. About how we recycle waste motor oil to diesel, we take our 10 ton latest waste motor oil distillation machine for an example.

Waste motor oil distillation machine new design

Waste motor oil distillation machine new design

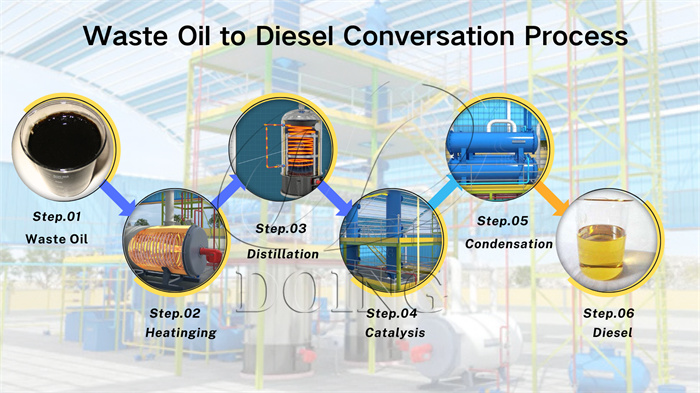

The process of waste motor oil to diesel is mainly composed of 4 different steps in order to get high grade diesel: distillation, catalytic, cooling, and further purification

The first step of waste motor oil (WMO) to diesel --oil distillation.

Waste motor oil belongs to heavy oil, mainly composed of long-chain hydrocarbons ,which is heavier and has higher density than diesel fuel. To make it become lighter, its long-chain hydrocarbon has to be cracked down into the short one, so the first step is distillation. Through high-temperature distillation, waste motor oil is converted into oil gas.

Waste motor oil distillation machine distillation system

Waste motor oil distillation machine distillation system

The second step of waste motor oil (WMO) to diesel -- catalytic refining

The distilled oil gas will go through the catalytic tower of our waste motor oil to diesel machine for further refining. Two different kinds of catalysts inside the tower work together to filter the distilled oil gas and meanwhile pyrolyze the heavier oil fractions.

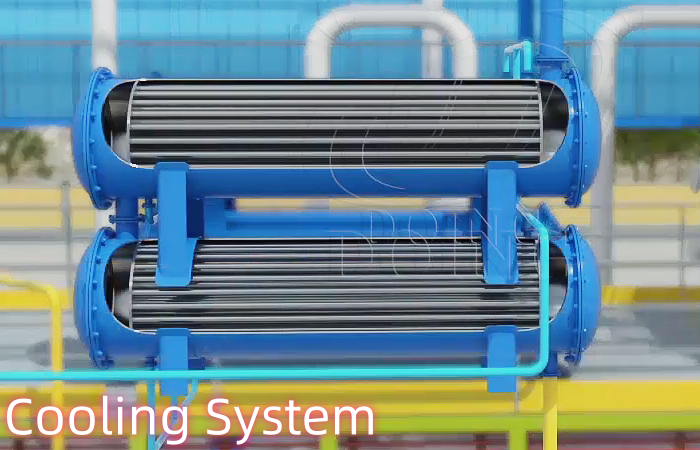

The third step of waste motor oil (WMO) to diesel-- oil gas cooling

The distilled oil gas after catalytic treatment will flow into cooling system of our waste motor oil to diesel machine for cooling down and then collected the generated oil into temporary oil tanks.

Cooling system of waste motor oil distillation machine

Cooling system of waste motor oil distillation machine

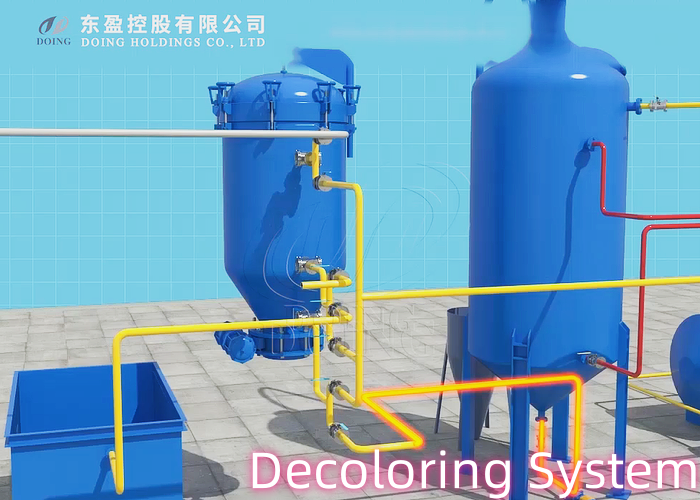

The forth step of waste motor oil (WMO) to diesel-- oil further decoloring and exhaust gas purification

The oil in the temporary oil tank is transported to the decolorization pot, white clay is added and stirred for decolorization, and then the oil fully mixed with the white clay is pumped into the leaf filter to obtain a clearer oil, which is then finely filtered to remove impurities.

The non-condensable oil and gas in the condensing system is purified by a water seal and used as fuel to heat the distillation reactor.

Waste motor oil distillation machine docoloring system

Waste motor oil distillation machine docoloring system

The above is the general design and process of our waste motor oil (WMO) to diesel machine.

So what aspects need to be considered to construct such a waste motor oil (WMO) to diesel plant? DOING briefly lists a few for you:

1.Market research: Understand the market supply and demand, price trends, and competitor situations of waste engine oil and diesel, and evaluate the feasibility and potential benefits of the project.

Market of recycled waste motor oil

Market of recycled waste motor oil

2.Factory site selection: Select a suitable site with convenient transportation, sufficient water and electricity supply, and far away from residential areas and water sources, while complying with local urban planning and environmental protection requirements.

3.Choose a reliable supplier to a buy waste motor oil (WMO) to diesel machine

DOING waste motor oil distillation machine

DOING waste motor oil distillation machine

For more precautions on waste motor oil (WMO) to diesel plant construction, recommended reading: How do you start a waste oil to diesel recycling plant step by step?

If you wanna get more information about the design, construction, profit analysis, etc. of this waste motor oil recycling project, please do not feel hesitated to contact with us.

PREV:How do you dispose of used lubricants?

PREV:How do you dispose of used lubricants?

NEXT:How to control the cost of waste tire pyrolysis equipment?

NEXT:How to control the cost of waste tire pyrolysis equipment?

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated

-

DY-C-50 fully continuous tire pyrolysis equipment put into operation in Russia

-

15 TPD used tyre pyrolysis machine produced fuel oil in Brazil

-

Waste tire to diesel plant project installed in South Africa