How to control the cost of waste tire pyrolysis equipment?

For customers engaged in waste tire pyrolysis, a plethora of options exist in terms of equipment capacity, material, design, and configuration. DOING is dedicated to assisting customers in identifying the most suitable and cost-effective solutions. So, precisely what are the pivotal factors in controlling the cost of waste tire pyrolysis equipment? Unquestionably, equipment capacity, material selection, reactor design, and configuration all play crucial roles.

DOING waste tire pyrolysis equipment

DOING waste tire pyrolysis equipment

1. Capacity selection

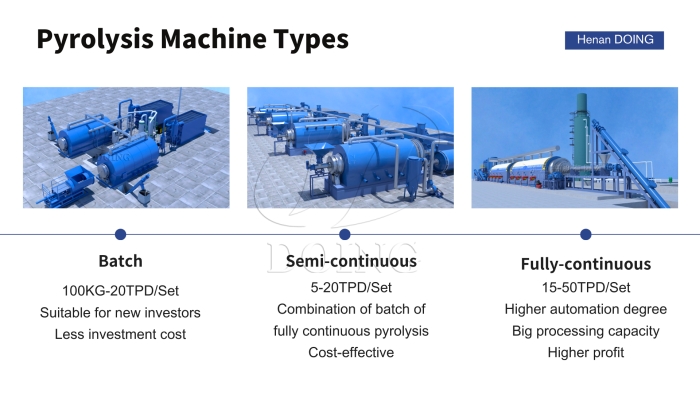

The larger the processing capacity of waste tire pyrolysis equipment, the higher the steel and labor costs required. DOING provides 100kg/500kg/1TPD/2TPD/5TPD/10TPD/12TPD/15TPD/18TPD/20TPD/30TPD/40TPD/50TPD waste tire pyrolysis equipment. Waste tire pyrolysis equipment types includes skid-mounted type, batch type, semi-continuous, fully-continuous type waste tire pyrolysis equipment. Customers need to carefully assess their actual processing needs to strike a balance between capacity and cost.

Types of DOING waste tire pyrolysis equipment

Types of DOING waste tire pyrolysis equipment

2. Reactor Material Selection

The choice of steel material for the reactor is a significant cost determinant. Different materials not only influence the initial wate tire pyrolysis equipment cost but also its lifespan. For instance, DOING's standard reactor material of waste tire pyrolysis equipment is the professional Q245R and Q345R boiler sheet materials. These options typically meet most customer requirements while offering good cost-efficiency. However, depending on specific customer demands, DOING can also provide customizations, such as using stainless steel. This upgrade enhances corrosion resistance and extends the service life of the waste tire pyrolysis equipment, albeit at a potentially higher cost. Customers should weigh the long-term benefits against the immediate cost implications.

DOING waste tire pyrolysis equipment reactor made

DOING waste tire pyrolysis equipment reactor made

3. Reactor design selection

The design of the reactor also affects the cost. The price of some waste tire pyrolysis equipment suppliers on the market is very low, but the flat-head head used in the reactor design has poor compression performance. However, the DOING reactor head uses a one-piece pressing technology, which has good pressure resistance but relatively high cost. Nevertheless, the enhanced safety and durability it provides can be well worth the investment in the long run, safeguarding the overall operational efficiency and reducing potential maintenance and replacement costs.

DOING waste tire pyrolysis equipment reactor design

DOING waste tire pyrolysis equipment reactor design

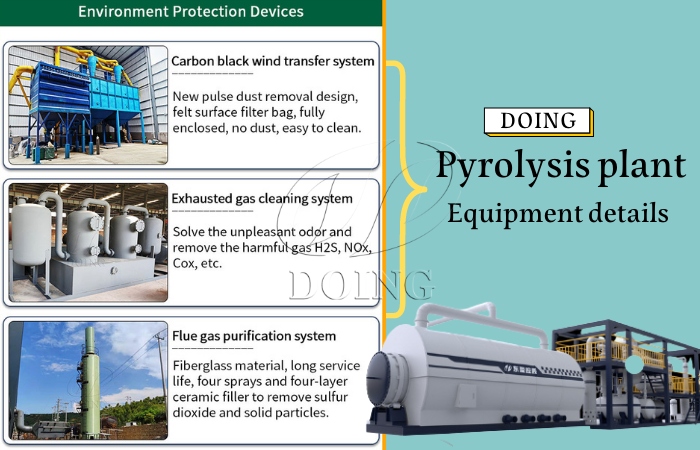

4.Configuration

If you want to meet the national environmental emission standards, you can also configure environmental purification equipment treatment systems on waste tire pyrolysis equipment, such as desulfurization towers, combustion chambers, dust removal equipment, tail gas purification treatment equipment, carbon black wind transport system, pulse dust removal box. Although adding these configurations incurs additional costs, it not only ensures compliance with regulations but also mitigates potential environmental impacts, safeguarding the long-term viability of the operation.

Environmental system waste tire pyrolysis equipment

Environmental system waste tire pyrolysis equipment

After this description, the customer may have a general understanding of the factors that control the cost of waste tire pyrolysis plant. If you want to buy the most cost-effective waste tire pyrolysis equipment that is safe and environmentally friendly to recycle the waste tires and make a huge profits, please call DOING or visit in person.

PREV:Design and construction of waste motor oil (WMO)to diesel machine

PREV:Design and construction of waste motor oil (WMO)to diesel machine

NEXT:How do I improve the profit of a waste oil to diesel distillation business?

NEXT:How do I improve the profit of a waste oil to diesel distillation business?

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated