Is pyrolysis a good investment?

Is pyrolysis a good investment? The short answer is yes—provided you choose the right technology and partner. Rising landfill fees, soaring fuel prices and strict environmental regulations are pushing businesses toward profitable waste-to-value solutions. Among them, pyrolysis stands out because it converts scrap tires, plastics, oil sludge into high-value pyrolysis oil, carbon black and syngas while eliminating disposal costs. DOING has supplied pyrolysis plants in 90+ countries since 2011. This article DOING introduces you to the investment potential of pyrolysis.

1.Low feedstock cost:

In many regions, scrap tires, mixed plastics, and oil sludge are often available free of charge, and recycling them is even subsidized.

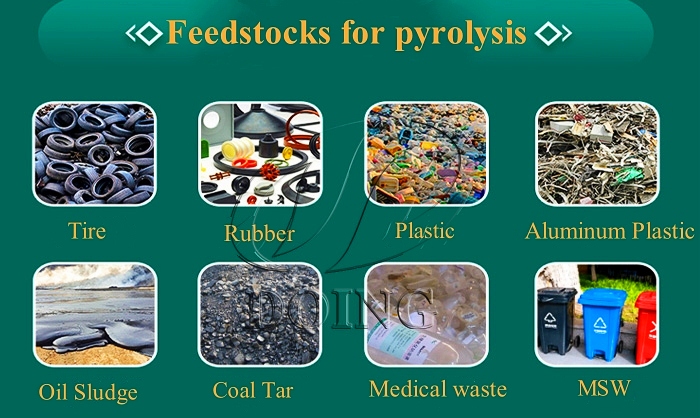

Raw materials that can be recovered by pyrolysis

Raw materials that can be recovered by pyrolysis

2.Strong market demand products:

Pyrolysis oil: A diesel substitute used in heavy fuel oil generators, boilers, and industrial heating. It can also be purified into diesel used for diesel generators and heavy machinery through DOING distillation machine. Global demand for such fuels is projected to grow 7% annually by 2030.

DOING waste to fuel recycling plant

DOING waste to fuel recycling plant

Carbon black: A key ingredient in rubber manufacturing and construction.

Syngas: Used to power the pyrolysis process, reducing reliance on external energy sources.

3.Highly profitable and rapid payback:

Let's take the 12tpd waste tire pyrolysis plant most commonly used by foreign customers as an example:

According to the feedback from foreign customers, the price of tires is approximately $120 per ton. The daily raw material price is: 12*120= $1440. The environment-friendly pyrolysis plant produced by Henan DOING can produce about 5.4 tons of oil, 4.8 tons of carbon black, and 1.8 tons of steel wire daily. The profit from tire oil is $5.4 * 900 = $4,860; the profit from carbon black is $4.8 * 200 = $960; and the profit from steel wire is $1.8 * 700 = $1,260, for a total daily profit of $7,080. Workers cost $200 / day (two people), electricity consumption 25*10=250KW. The profit per day is at least 4500-5000 dollars per day. Thus it can be seen that the profit of doing pyrolysis project is very considerable.

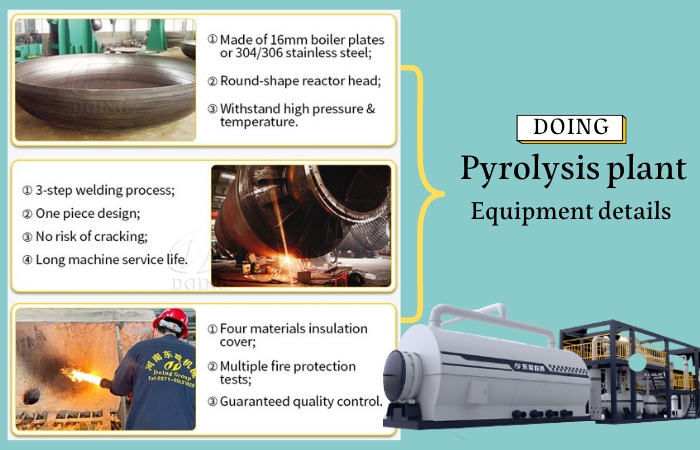

DOING waste to fuel pyrolysis plant advantages

DOING waste to fuel pyrolysis plant advantages

The investment return period of DOING pyrolysis plant is generally about 3-4 months, depending on the investment amount, processing capacity the customers want to install, the configuration customers would like to adopt, and other factors. Furthermore, DOING pyrolysis reactors are constructed using national standard materials, with customizable 304/306/314/316 stainless steel options. They offer a service life of over 5 years and require virtually no maintenance, ensuring continuous returns. This demonstrates the considerable profitability of pyrolysis projects.

4.Scalability:

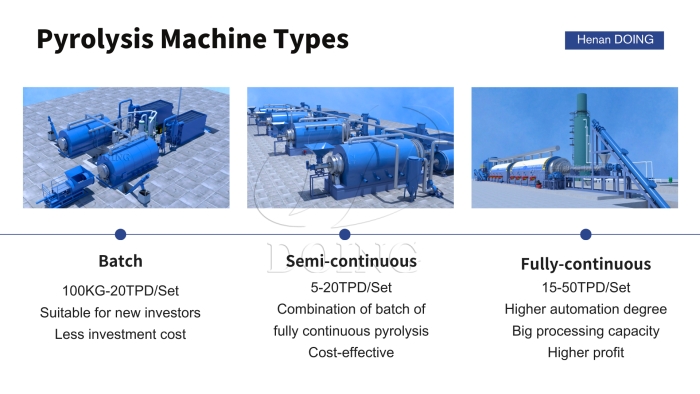

DOING can provide pyrolysis plant with different processing capacity, ranging from 100kg to 50 tons per day, to meet different customer processing requirements.

Skid-mounted mini plant (0.1–5TPD) is compact, requires minimal floor space, requires no complex civil engineering, and has a quick installation cycle. It is mainly used for preliminary testing, to prove to the government that the project is pollution-free, or to show to investors for use in larger projects.

Batch type pyrolysis plant (5–20TPD) has a relatively simple structure, requiring continuous downtime to process feedstock and remove product, with repeated cooling and reheating, completing a cycle in an average of 22 hours. It is economical and easy to operate.

DOING waste to value pyrolysis plant

DOING waste to value pyrolysis plant

Semi-continuous type pyrolysis plant (5–20TPD) combines the process designs of a batch pyrolysis plant with those of a fully continuous plant. A spiral auger feeder improves feeding efficiency, while a spiral auger discharger enables high-temperature slag discharge, saving cooling time. This allows for three furnaces in two days, effectively improving production efficiency.

Fully continuous type pyrolysis plant (15–50TPD) allows for continuous feeding and slag discharge, 24/7 operation, and can run continuously for 40 days, significantly improving production efficiency and labor costs.

Tips: The larger the processing capacity, the more profit, and the shorter the return period.

DOING full-continuous pyrolysis plant advantages

DOING full-continuous pyrolysis plant advantages

If you have enough waste and want to get rid of it and make a profit at the same time, pyrolysis projects are definitely a good option. But this requires the customer to find a suitable supplier, to provide mature technology, environmental protection and safe equipment, guaranteed after sale. DOING can be one of your top priorities. If you have any question, please leave DOING a message to get the contact of the professional business manager.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated