Is waste motor oil recycling and refinery a good business?

Investing in a waste motor oil recycling and refinery machine can be a promising business venture, but like any business, it comes with its own set of challenges and considerations. In this article, we’ll explore why investing in a waste motor oil refinery machine could be a good business opportunity, the potential benefits, and the challenges to consider before making a decision.

Waste motor oil for recycling and refinery

Waste motor oil for recycling and refinery

Why Waste Motor Oil Recycling is a Good Business?

1. Environmental Impact and Regulation Compliance

One of the key advantages of investing in a waste motor oil recycling and refinery business is the positive environmental impact. Proper disposal and recycling of used motor oil reduce pollution and conserve natural resources. Countries around the world are imposing stricter regulations on waste oil disposal, making it increasingly difficult for companies and individuals to improperly discard waste oil. Recycling waste oil can provide an eco-friendly solution while helping businesses comply with local and international environmental laws.

2. Growing Market for Recycled Oil

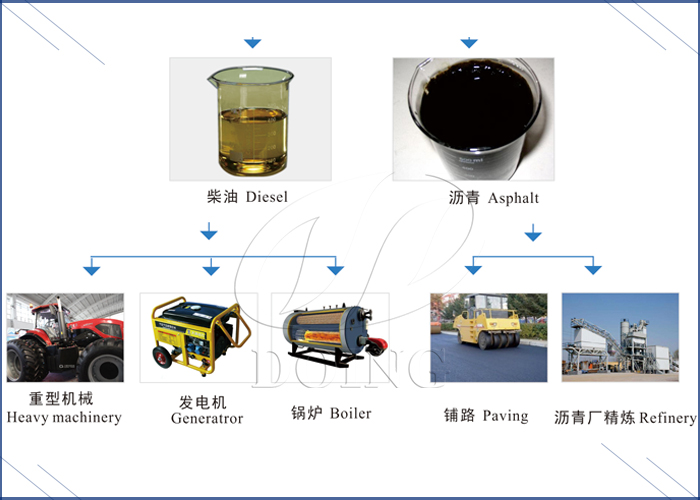

Waste motor oil recycling involves the collection, purification, and re-refining of used motor oil to remove contaminants, so it can be reused. This process creates a valuable product that can be resold and reused as high-quality alternative diesel fuels for trucks, ships, boats, heavy machinery, diesel generators, etc. At present, the global demand for recycled oil is steadily increasing, driven by the need for sustainable materials in the industrial sector. This growing market for recycled oil products creates a reliable and recurring revenue stream for businesses that specialize in waste oil recycling.

Market of diesel extracted from waste motor oil

Market of diesel extracted from waste motor oil

3. Cost-Effective Operations

Waste motor oil recycling can be a cost-effective business model when compared to other oil production methods. The process of collecting used oil is generally less expensive than extracting crude oil from the earth, especially when the supply chain for used oil is well-established. Furthermore, the refining process has become more efficient with advanced machinery, reducing the overall cost and increasing profitability.

4. Renewable Resource and Sustainability

Waste oil recycling not only helps reduce the need for new oil extraction but also contributes to the broader goal of sustainability. By reprocessing used oil, businesses are creating a circular economy where products are reused and waste is minimized. This aligns with the growing global trend towards sustainability and can give companies a competitive edge in an increasingly eco-conscious marketplace.

Waste motor oil recycling refinery final products and their applications

Waste motor oil recycling refinery final products and their applications

Key Considerations Before Investing

While waste oil recycling presents an attractive business opportunity, it’s important to be aware of the challenges involved. Here are a few key considerations before investing in a waste oil recycling and refinery business:

1. Supply Chain Management

A consistent supply of waste oil is essential for maintaining smooth operations. Establishing reliable collection networks and building relationships with oil change centers, automotive workshops, and other sources of waste oil is crucial to the success of the business. Competition for waste oil can also be fierce in certain regions, so careful planning is necessary.

2. Waste Motor Oil Recycling Refinery Technology and Training

Waste motor oil recycling and refining is a highly technical process, which involves waste oil distillation and catalysts refinery. In order to achieve high profitability, it is necessary to purchase high-quality waste oil recycling refinery machine from professional manufacturers, and understand its heating method, catalytic technology, oil yield, installation items and other contents.

Investing in the right machinery is only part of the equation—business owners must ensure they have skilled workers to operate the equipment efficiently. Proper training for staff and ongoing technological improvements are important factor.

DOING waste motor oil recycling refinery machines

DOING waste motor oil recycling refinery machines

3. Initial Investment and Operating Costs

Purchasing and operating a waste oil recycling and refinery machine requires upfront capital investment. While the long-term returns can be promising, the initial costs for equipment, machinery, and setup can be high. Additionally, early stage waste oil treatment scale planning, ongoing maintenance and operational expenses must be carefully managed to ensure profitability.

Despite the challenges, with the right resources and strategies in place, waste oil recycling can be both a financially rewarding and environmentally impactful enterprise.

Waste motor oil recycling refinery project case

Waste motor oil recycling refinery project case

Henan DOING waste oil recycling refinery machine is sepcically designed for refining motor oil or waste oils to light diesel. This whole refining process includes distillation , cooling, decloring and deordoring system. And the diesel oil yield can reach 85%, which is a really good prject to get maximum profits. DOING waste oil recycling refinery machine has different models, catalyst technology and processing capacity, which is very popular with the customers due to its high efficiency and safety. If you want to know more details, you can contact with DOING group.

PREV:How do I improve the profit of a waste oil to diesel distillation business?

PREV:How do I improve the profit of a waste oil to diesel distillation business?

NEXT:What configurations can DOING provide for waste oil distillation plant?

NEXT:What configurations can DOING provide for waste oil distillation plant?

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated