What is waste lubricating oil purification and recovery system?

Waste lubricating oil purification and recovery system is a device that can purify and recycle waste lubricating oil. Next, I will explain what the waste lubricating oil purification and recovery system is from the aspects of the function, composition, working process, product and product use of the system.

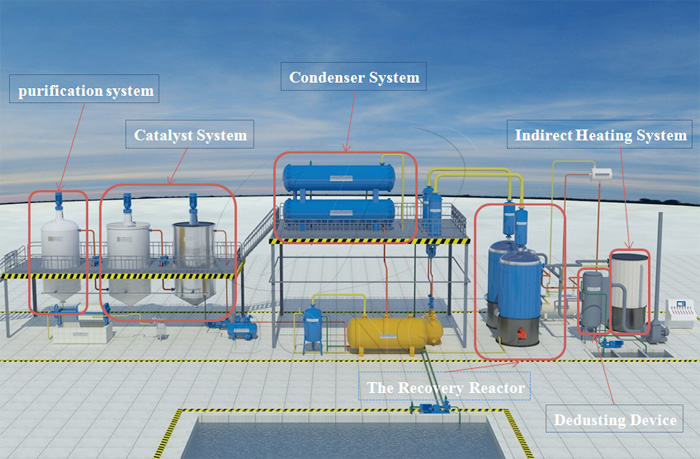

Waste lubricating oil purification and recovery system

Waste lubricating oil purification and recovery system

If abandoned lubricating oil is discarded, it will bring great harm to the ecological environment and cause huge energy waste. The waste lubricating oil purification and recycling system is developed and manufactured for waste lubricating oil, which can purify and recycle waste lubricating oil into diesel oil.

The main composition of waste lubricating oil purification and recovery system

Waste lubricating oil purification and recovery system mainly contains the indirect heating system ,the recovery reactor, condenser system, catalyst system, purification system and dedusting device. The indirect heating system can greatly accelerate the distillation speed and save the heating fuel. The recovery reactor is the vertical design, which can achieve the automatic slagging. The condenser system can cool oil gas into diesel, we adopt the shell and tube condenser to ensure cooling efficiency and oil yield. The catalyst system can remove the odor and colloid from diesel. The purification system can further deep purify the diesel, and finally get light yellow diesel. The dedusting device can purify smoke, control pollution, and protect the environment.

The main composition of waste lubricating oil purification and recovery system

The main composition of waste lubricating oil purification and recovery system

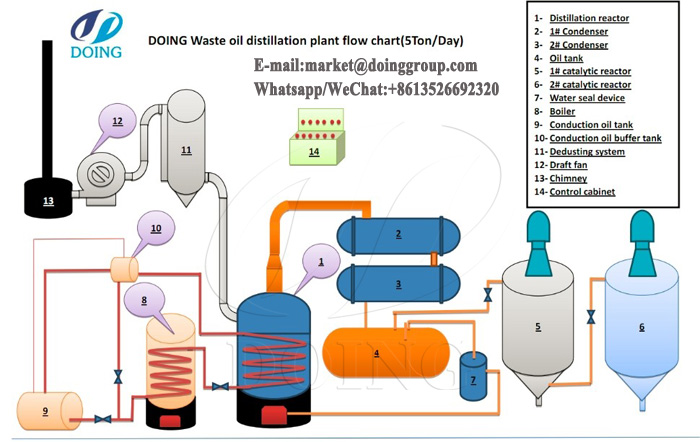

The working process of waste lubricating oil purification and recovery system

First put waste lubricating oil in the recovery reactor, and then open the indirect heating system to heat the reactor, when reaches a certain temperature, oil gas will be distilled out, through condenser system, the oil gas will be cooled into diesel, and then removed odor and colloid by catalyst system, you will get yellow-brown diesel, if you want the light-yellow diesel, you can add the purification system to further purify the diesel, eventually get better quality and better color diesel.

The working process of waste lubricating oil purification and recovery system

The working process of waste lubricating oil purification and recovery system

Product application

The diesel obtained from waste lubricating oil purification and recovery system can be used to the diesel burners, generators and tractors and so on.

If you want to deal with a large amount of waste lubricating oil, or looking for profitable projects, please feel free to contact us.

PREV:How to purify used engine oil?

PREV:How to purify used engine oil?

NEXT:How to choose the waste oil distillation plant in Malaysia?

NEXT:How to choose the waste oil distillation plant in Malaysia?

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

What is the Process of Waste Oil Distillation Plant and Its Advantages?

-

Horizontal vs Vertical Reactor for Waste Oil Distillation Plant

-

How much waste oil can be processed by waste oil recycling distillation plant daily?

-

Two Options for Liquid and Solid Catalyst Waste Oil Recycling Machines

-

-

-

How many ways are there to regenerate waste engine oil to diesel?

-

Successful Installation of 50-Ton Fully Continuous Oil Sludge Pyrolysis Equipment in China

-

Installation of DOING 30 tons of waste oil distillation machine project installed in Kazakhstan

-

-

-

Mexican customer's waste pyrolysis distillation plant were successfully installed

-

1TPD pyrolysis oil to diesel distillation plant installed in Thailand

-

Paper mill waste plastic to diesel pyrolysis distillation plant in Mexico successfully operated